Metal powders

Flowability and cohesion determination of metal powders using GranuHeap and GranuDrum

The GranuDrum is an instrument able to estimate the flow ability and the cohesion of granular materials by comparing the wave of powder under motion in a rotating drum. The obtained avalanche angle and cohesive index authorize a simple and fast comparison between various samples...

Principle

The GranuDrum is an instrument able to estimate the flow ability and the cohesion of granular materials by comparing the wave of powder under motion in a rotating drum. The obtained avalanche angle and cohesive index authorize a simple and fast comparison between various samples. The results give information about the adherence (static part of the flow) and the shear/friction part of the flow).

Therefore, several metal powders (granular materials recognized for the absence of surface interactions) were analyzed by using the GranuDrum instrument.

LEARN MORE ABOUT THE GRANUDRUM

The principal characteristics of these powders diverge in their grain size, their shape and the nature of studied material.

Description of the powders

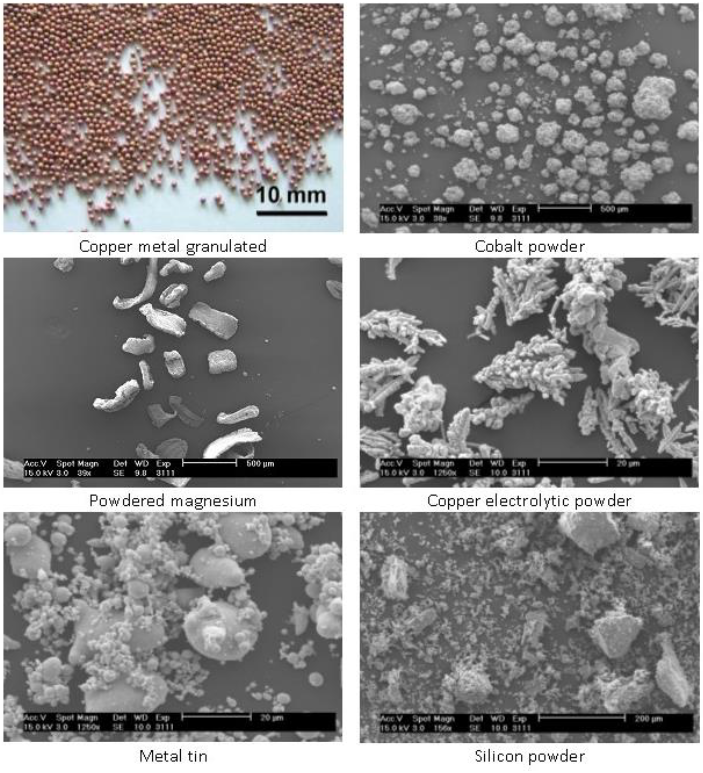

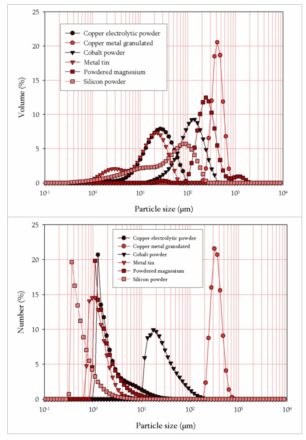

Figures 1 and 2 show pictures and particle size distribution of the metal powders studied.

Figure 1: Electron micrographs of the metal powders

Figure 2: Grain size distributions expressed a) in volume and b) in number for a powder cohesion study comparison

The combination of these data shows

Copper metal granulated powder is mainly composed by spherical particles with size ranging between 200 and 800µm.

Cobalt powder consists of pseudospherical compact grains with a lightly rough surface state. The size of the particles varies between 10 and 400µm. Powdered magnesium particles present a chips morphology with size varying between 100 and 1500µm. Copper electrolytic particles have an atypical shape such as dendrites morphology. The grain size distribution expressed extends from 1 to 100µm.

Tin powder shows pseudospherical grains with relatively smooth quality surface. The grain size population seems to be relatively wide (bimodal distribution). This observation is confirmed by the grain size distributions. On one hand, the figure 2a shows that the distribution varies from 700nm to 60µm and, on the other hand, the figure 2b illustrates the considerable weight carried by the particles ranging between 700nm and 4µm.

Silicon powder consists of a double population (bimodal distribution) with a total extent ranging between 700nm and 250µm (figure 2a). The number grain size distribution varies between 300nm and 3µm.

These results seem to agree with the observations carried out by scanning electron microscope where we can see (figure 1) simultaneously big angular massive particles accompanied by smaller.

Results

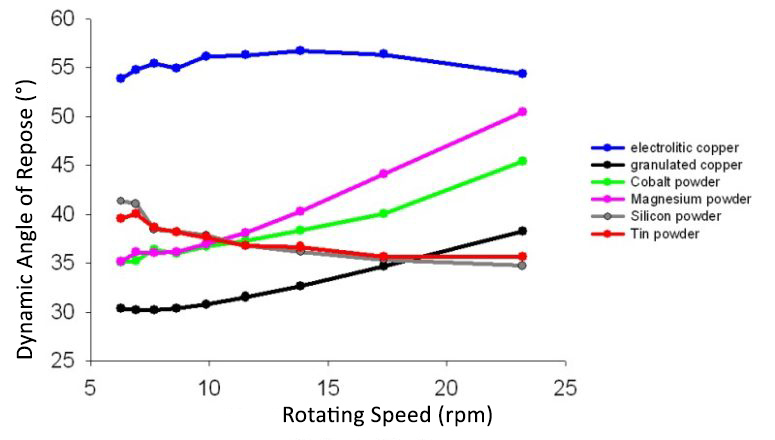

Figure 3 shows the evolution of the avalanche angle (static part of the flow) versus the rotating speed for each metal powder.

Figure 3: flow angles versus the rotating speed stress for different metal powders

By considering figure 3, we can categorize these metal powders in 3 main groups:

- Powders which the flow ability becomes poorest depending on the rotating speed (granulated copper, cobalt, and magnesium powders). These powders can be characterized by a shear thickening behaviour when in motion;

- Powders which the flow ability is improved when the rotation speed is increased (silicon and tin powders). These powders are characterized by a shear thinning behaviour when in motion;

- Powder which the flow ability stays stable under the stress effect. This powder is not affected by the rotating speed (electrolytic copper).

So, at each rotating speed, as high is the flow angle, as high is the adherence behaviour (static component of the flow).

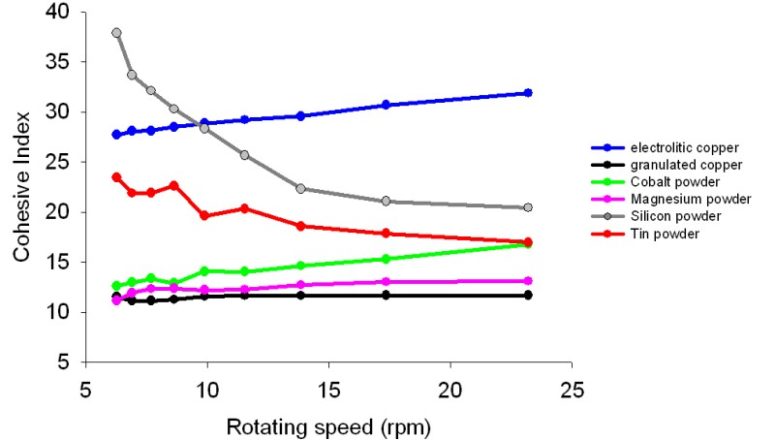

Figure 4: Cohesive indexes versus the rotating speed stress for different metal powders

We can observe on figure 4, that granulated copper, magnesium and cobalt powders are characterized by the lowest cohesive indexes (shear/friction component of the flow). This behavior is due to the particle size (figure 2) and the nature of the particles.

Indeed, these metallic powders are defined by high specific gravity. So, when the bed powder is under motion, there is no important cohesion between the particles, even for particles with special shape (magnesium powder-chips morphology): the weight component fixes/establishes the flow ability of these powders and granular materials.

Concerning silicon and tin powders, we can observe that the initial cohesion is very high (shear/friction component of the flow). This behavior can be due to the presence of small particles in the powders which increase the friction component of the powder. However, as more powders are in motion, as the reduction of the cohesive index is high.

This may be explained by the air/voids present between the particles due to the rotating motion.

This air acts as lubricant (minimize the contact numbers between the grain particles) and allows decreasing the cohesion between the grains and increasing the flow ability of the powders.

Electrolytic copper is characterized by a high cohesive index due to the particle size but also more particularly due to the special shape of the particles (dendrite aspect – figure 1) which increases the bonding between the particles as well as in the static part (flow angles) of the powder bed as in the dynamic component of the flow.

Conclusion

These results show that the GranuDrum instrument allows categorizing metal powders depending on their respective shape and grain size distribution. This instrument gives general information on the flow ability of powders in motion.

LEARN MORE ABOUT THE GRANUDRUM

✓ Moreover, it is also possible to obtain information about the adherence (static part of the flow) and the cohesion (dynamic component of the powder flow) in the powder.

✓ With the GranuDrum, it is able to measure the flow ability of dense granules and powders in a wide range of particle size.

✓ GranuDrum instrument can also be used as a rheometer (using air as dispersive medium) and gives important information on the behavior of powders in motion.

So, it is able to define if powder is characterized by a shear thinning, a shear thickening behavior or if it is independent of the rotating speed stress applied on it.

LEARN MORE ABOUT THE GRANUDRUM

✓ GranuDrum allows also to resulting if the powder presents or not a hysterisis loop (differences in the up and down avalanche/flow and cohesive index curves). In other words, if the powder has the same flow ability and cohesion index before and after the measurement. In this special case of metal powders, no hysterisis has been detected. Thus, powders have the same behavior before and after the measurement in all rotating speed range studied. These powders do not incur the effect of the rotating stress. On the other hand, in the case of these metal powders, the shape of the particles, the particle size and size distribution are important factors which can significantly contribute to the flow ability and the cohesion in powders.

✓ In these conditions, other specific techniques such as the GranuHeap, GranuPack and GranuFlow have to be used to quantify the other components/parts of the flow-ability of the powders.