Papers

Study and modeling of an intermetallic powder bed behavior for solid state hydrogen storage

Chrisale Ngueloheu Yeda.Étude et modélisation du comportement d’un lit de poudre intermétallique pour le stockage solide d’hydrogène. Mécanique des fluides [physics.class-ph]. Université Marie et

Louis Pasteur, 2025. Français.NNT:2025PAST2016. tel-05319523

Solid‑state hydrogen storage relies on metallic powders capable of absorbing and releasing hydrogen. During cycling, these powders undergo expansion, contraction, fragmentation, and rearrangement, which in turn generate stresses on the reservoir walls. Understanding these granular‑scale mechanisms is essential for predicting the mechanical response of storage systems.

In his doctoral thesis “Study and Modeling of the Behavior of an Intermetallic Powder Bed for Solid‑State Hydrogen Storage” (2025), Chrisale Ngueloheu Yeda investigates the mechanical behavior and flow properties of TiFe‑Mn alloy powders. A central part of the work consists of characterizing the powder under different flow regimes and using these measurements to calibrate discrete element (DEM) simulations.

To obtain reproducible experimental input data, several Granutools instruments were used to quantify flowability, compaction behavior, and cohesion across powders of different particle‑size distributions.

Experimental Characterization Using Granutools Instruments

GranuDrum - Dynamic Flow and Cohesion

The GranuDrum was employed to measure:

- dynamic angle of repose under increasing rotation speeds,

- interface fluctuations used to compute a cohesion index,

- flow regime transitions (avalanche → rolling → cascading),

- segregation effects in mixed particle‑size samples.

These measurements revealed clear differences between fine, coarse, and polydisperse powders. In particular, fine powders showed stronger cohesion and larger angles of repose, while coarse powders showed low cohesion and more stable flow.

GranuPack - Compaction and Density Evolution

With a controlled tapping protocol, the GranuPack provided:

- bulk and tapped densities,

- Hausner ratio and Carr index,

- characteristic tapping number,

- compaction slopes reflecting rearrangement kinetics.

These results helped quantify how different particle‑size distributions reorganize under confinement, an important factor when modeling the stress transmission within a powder bed during hydriding cycles.

GranuHeap - Static Angle of Repose

The GranuHeap was used to measure the static angle of repose and the overall geometry of the freely formed pile.

The angle of repose measurements provided a consistent comparison between powders, confirming trends observed with the GranuDrum and GranuPack.

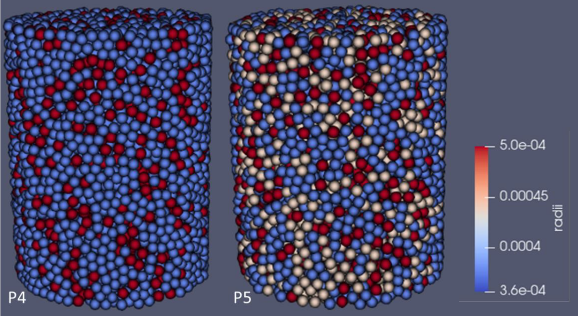

Integration into DEM Modeling

The experimental results obtained with Granutools instruments were used to:

- determine interparticle friction and cohesion parameters,

- calibrate DEM models in YADE for GranuDrum, GranuPack, and compression tests,

- simulate the “breathing” of the bed during hydriding,

- evaluate radial and tangential stresses applied to cylindrical reservoirs.

Simulations reproduced several phenomena observed experimentally:

- a polynomial stress distribution, with higher stresses in the lower part of the reservoir,

- increased stresses when particle size decreases or when fill ratio increases,

- consistent trends with segregation and densification observed in physical tests.

The combination of dynamic, quasi‑static, and static powder characterizations provided by GranuDrum, GranuPack, and GranuHeap formed the experimental foundation for the thesis’ DEM modeling work.

These measurements allowed the identification of key mechanical and interaction parameters governing the behavior of TiFe‑based hydride powders, supporting a more accurate simulation of powder‑bed evolution during hydrogen cycling.