Application notes

Evaluation of powder settling with the GranuDrum

In this work, we present how the settling of a powder can be measured by using the method proposed by the GranuDrum.

Introduction

Powder settling is a phenomenon intimately linked to fluidization processes. These processes are largely used in various industries (pharmaceutical, food, chemical…) for drying, dispersing, or other applications. If on the one hand, the fluidization of a given powder must reach specific criteria, on the other hand, the settling of the powder can be a limiting factor. If the powder densifies too fast after the end of the fluidization, or during bag filling, this can result in an inadequate processability of the powder due to changes in flowability and bulk density. Therefore, powder settling should be quantified to prevent issues coming from unexpected and fast powder settlement. In this work, we present a method based on rotating drum analysis to measure settling with the GranuDrum.

GranuDrum

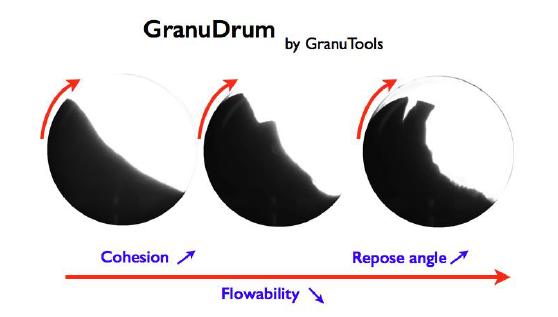

In this work, the GranuDrum was used to measure powder settling. This instrument is an automated powder flowability measurement method based on the rotating drum principle. A horizontal cylinder with transparent sidewalls called drum is half-filled with the powder. The drum can rotate different angular velocities ranging from 0.1 rpm to 250 rpm. A CCD camera takes snapshots (40 images separated by 1s) for each angular velocity. The air/powder interface is detected on each snapshot with an edge detection algorithm. Afterwards, the average interface position and the fluctuations around this average position are computed. From this image analysis, various metrics are computed, allowing a quantification of the powder cohesiveness, flowability, spreadability, aeration, rheology...

Figure 1: Sketch of the GranuDrum instrument principle.

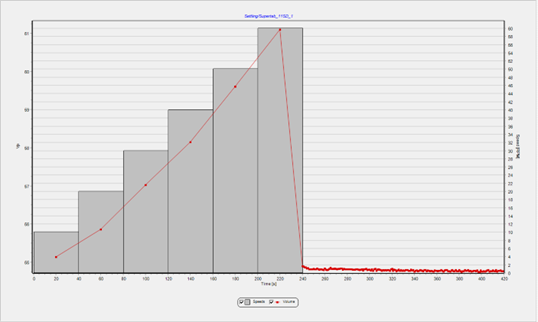

In this work, the settling mode was used to quantify the ability of the powder to de-aerate after the cell rotation is stopped. First, the powder is aerated gradually with an increasing speed sequence as presented in Figure 2. An increasing speed sequence of 10;20;30;40;50;60 rpm, each having a duration of 40 s, was used to aerate the powder. As can be seen, the volume effectively increases as the speed increases.

Once this sequence is done, the speed is abruptly decreased until it reaches 0 rpm. Then the settling starts and pictures are taken each second. From these pictures, the volume of the powder is measured and recorded.

LEARN MORE ABOUT THE GRANUDRUM

Figure 2: Volume evolution with time by following the protocol of the settling mode.

Material

Three different powders: natural Graphite (Graphite), Titanium alloy (Ti6Al4V), and Lactose (SuperTab11SD), used in various applications (tableting, electrode production, additive manufacturing…) were selected to measure settling for a large panel of representative powders.

Results

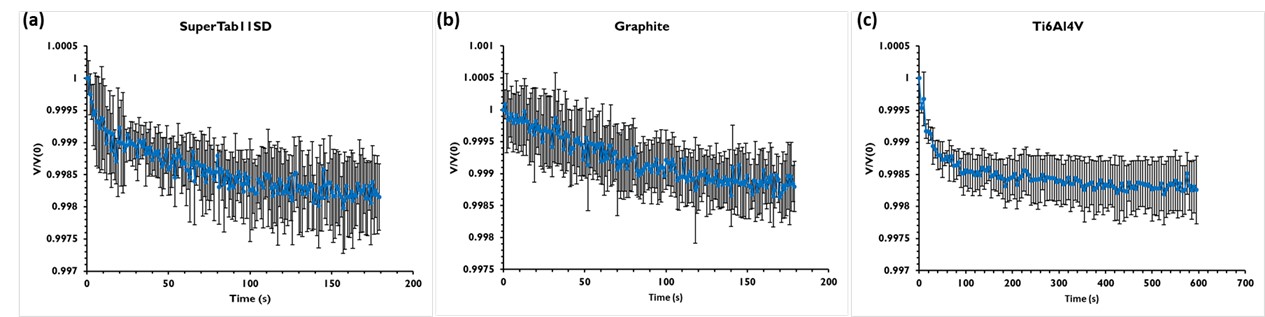

In Figure 3, the normalized volume V/V0, is presented as a function of time just after the powder stops in static conditions, with the volume of powder just after the rotation is stopped. A decrease in normalized volume is seen for each curve, due to the gradual settling of the powder.µ

Figure 3: Settling of the three tested powders.

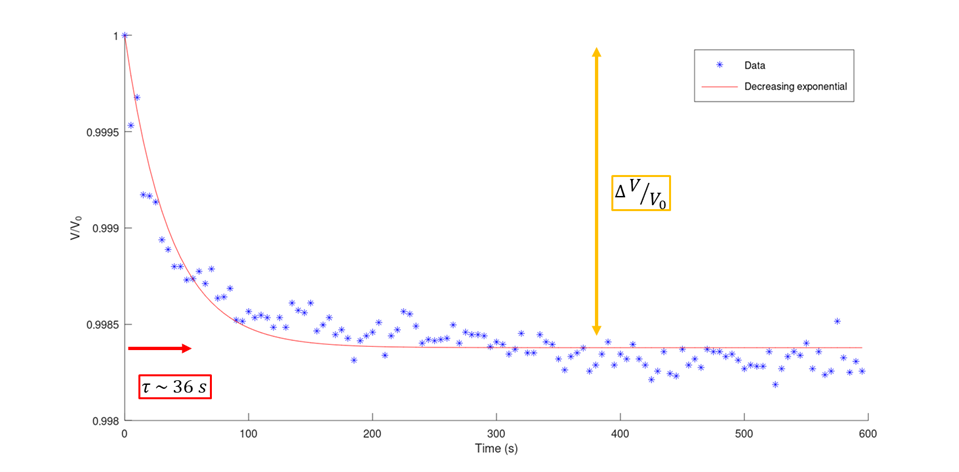

From these curves, the typical time τ and the amplitude of the settling ∆V / V0 can be computed to quantify the settling. A decreasing exponential law

(V(t))/V0 = (1-V∞ - V0) e^(-t/τ) + V∞ / V0

can be adjusted to the data to estimate these metrics, with V∞ the volume reached after an infinite time (∆V = V∞ - V0). The approach is illustrated in Figure 4 for the Ti6AI4V powder.

Figure 4: Evaluation of the settling with metrics computed from a decreasing exponential law fit.

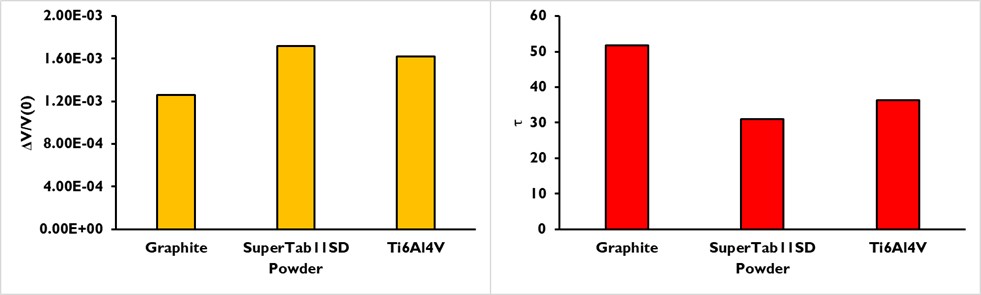

In Figure 5, the metrics obtained for the different powders are presented, highlighting the variety of dynamics for different powders. On the one hand, the larger ∆ V / V_0 the more intensive the settling, meaning that the powder has a large ability to settle after aeration. On the other hand, τ gives the typical time that takes the powder to reach its steady state volume after settling. For instance, the Graphite powder has less intensive settling but the largest time to reach the steady state compared to the other powders. On the contrary, the SuperTab11SD has the largest settling amplitude but is fast to reach the final volume.

Figure 5: Results of the metrics τ and ∆ V / V_0 obtained for the three powders

Conclusion

With the method proposed by the GranuDrum, the settling of a powder can be measured. The amplitude and the dynamic of the settling can be evaluated from the decrease in volume obtained after aeration and then an abrupt stop of the dynamic conditioning. A decreasing exponential law fit of the experimental data allows to evaluate the amplitude and the dynamic τ characterizing the settling.

With the simplicity of the method, the large panel of speed sequence, image acquisition, and the facility of cleaning the cell, the GranuDrum brings new possibilities for characterizing settling in a fast and reproducible way for process optimization.