Blog

How to quantify powder segregation using the GranuPack

Discover how the GranuPack instrument can help measuring powder segregation in an accurate, reproducible and easy way.

Introduction

Granular segregation is a problem in many industrial processes. For example, in pharmaceutical industries, medicines have a narrow tolerance for the variability of the active material mass in the powder blend. In the food industry, many different powders are mixed to obtain a product for which the quality must be constant. Powder segregation is a big issue in such applications since it leads to variation in the concentration of each powder species in a produced batch. Therefore, when this batch is divided into small parts, the quality can vary from one sample to another, and chemical or physical properties can be affected after processing the powder blend.

Although powder segregation has been known for a long time, it remains difficult to avoid. The processes need to be improved to limit this phenomenon. For that, a better understanding and above all a quantification of segregation is necessary. This needs a dedicated tool for measuring segregation in an accurate, reproducible, and easy way.

Why using the GranuPack

The tapped density measurement is a well-known method used to measure the bulk density of a powder and its ability to densify under mechanical solicitation. In addition, small differences in the powder properties result in differences in its bulk density and its packing dynamics. The GranuPack instrument is an automated and improved tapped density measurement that allows to measure these characteristics of the powder in a reproducible and accurate way without operator dependency.

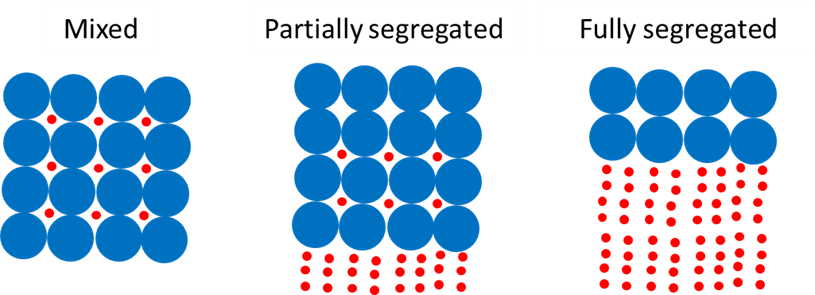

Granular segregation is known to affect the bulk density of a powder. Indeed, for instance, when coarse particles are separated from fine particles, the fines cannot fill the void between the large particles and optimize the packing. Therefore, granular segregation leads to a decrease in bulk density compared to a homogeneous blend.

Depending on the level of segregation, this decrease in bulk density can be small and requires the precision of an automated procedure as preconized by the GranuPack protocol. Therefore, it is possible to sample a produced batch of powder and to compare its bulk density with the homogeneous blend to evaluate its level of segregation. The Segregation Index, defined from the deviation between both bulk densities, can thus be used to quantify the level of segregation of the produced batch. This quantification helps for better control of the process and the resulting product. Additionally, an improvement of the process can be made by adjustment of the production parameters and the quality control of the produced batch.

Conclusion

Granular segregation is a phenomenon that causes issues in many different industrial fields and needs to be fixed. Therefore, it is necessary to develop a dedicated method to measure and quantify the level of segregation of a produced batch to have better control of the phenomenon in industrial processes.

By systematically measuring segregation and adapting the process to reduce it, the encountered issues can be removed or at least restrict their effect on the final product. The GranuPack offers an automated and precise protocol that allows the operator to quantify segregation for quality control and process optimization.